So I've picked back up on liquid engine design for the lander. This is a brief of what I'm pursuing so far for the combustion chamber

Stats:

- Thrust: 500lbf (2.22kN)

- Pc: ~300 psi (2MPa)

- Propellants: Liquid Oxygen, Ethanol 70%

- Mixture Ratio: 1.35

- 20% fuel boundary layer cooling

- 15 degree conical half angle

- L-star of 1 meter

- 45 degree contraction angle on converging section, for manufacturability

- Chamber Inner Diameter: 81mm

- Materials: 304/316 Stainless Steel

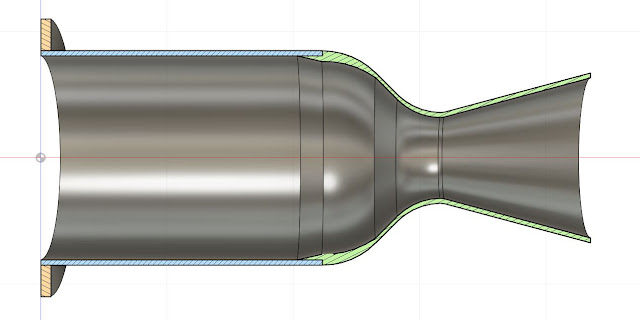

I am first going to manufacture the chamber in two parts.. the cylindrical section, and then the printed or CNC'd converging-diverging section which I plan to weld on. The former is based on this affordable part from McMaster Carr. It's 304 stainless with a weld bead down the center of it, and polished. I am a bit worried about the weld bead, but I know other chambers have been made similarly. The thickness is about 2mm, still checking to see if this checks out thermally.

The ID of the chamber material is supposedly very accurate, so I've added a taper to the C-D section that traverses the inside the the tube, and can be welded from the outside.

Here's Snort:

I've put out quotes for printing or CNC machining the C-D nozzle section and so far it only seems to be around $300 in stainless which is shocking to me.

If I can get each engine to be under $1k I'll be super happy. More to come on injector design and thermal analysis.. Need some friends to double check me :) Ideally, I'd like to print the injector and then weld it directly to the chamber, so I don't need to worry about fasteners, leaks, seals etc. Not sure if this is a good idea, but Armadillo had good luck with welding it all on there.